www.edgecam.com

Webinar recording of the latest product highlights for Edgecam 2015 R1

Live webinar recording which highlights the benefits & features of the latest release of Edgecam 2015 R1.

www.edgecam.com

Workflow for Wire EDM - Edgecam 2015 R1

Edgecam Wire EDM is now available within the Workflow environment. Furthermore, Edgecam 2015R1 offers full Machine Simulation, including stock and cross-section display.

www.edgecam.com

EWS - Edgecam 2015 R1 CAD-CAM

Numerous new commands have been added to Edgecam With Solids (EWS), our internal solid modelling application. An array of time-saving commands have been introduced such as the ability Copy/Move procedures and, create circular work-planes. To accelerate the design process, users may now import DXF and DWG files plus create both internal & external threads.

www.edgecam.com

Direct Picking - Edgecam 2015 R1 CAD-CAM

The Parallel Lace, Constant Cusp, Rest Finishing & Pencil Mill Cycles have all been enhanced to allow ‘direct picking’. This means that individual face features can be selected and the entire model will be protected. Furthermore, all 3D machining cycles can now directly select face features as containment boundaries. This will significantly reduce cycle preparation time.

www.edgecam.com

Rotary Axial Milling - Edgecam 2015 R1 CAD-CAM

A new Active Axis option has been added to the Mill Mode Dialog allowing users to select which axis is active during rotary axial machining. Potential machine tool “axis out of limits”, can now be avoided by selecting Rotary mode.

www.edgecam.com

Machining Order - Edgecam 2015 R1 CAD-CAM

An ‘Optimise Path’ function has been added to both the Roughing and Profiling cycles, thus allowing greater control over the toolpath.

Specifically you may now dictate the order in which regions are machined, significantly reducing the number of rapid toolpath movements.

www.edgecam.com

Custom Themed Ribbons - Edgecam 2015 R1 CAD-CAM

Edgecam 2015R1 introduces the ability to customise the default ribbon bar, altering the GUI appearance and saving it as a “Theme”. Custom ‘Themes’ can be exported to other Edgecam installations, and deployed across networks. To improve productivity, users can personalise their individual ‘Theme’ with frequently used commands, and add custom macros if so required.

www.edgecam.com

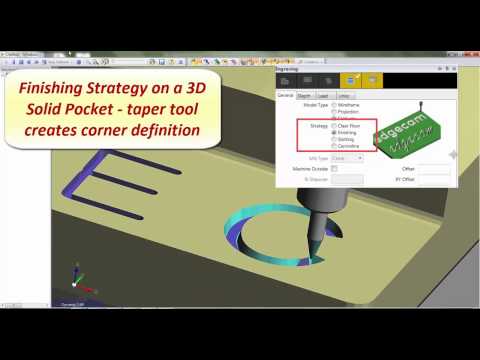

Engraving Cycle - Edgecam 2015 R1 CAD-CAM

Edgecam 2015R1 introduces a new Engraving cycle. This allows users to shape complex geometry corners and machine artwork profiles.

Using direct picking, the cycle works with a variety of geometric entities and offers four different types of strategies.

www.edgecam.com

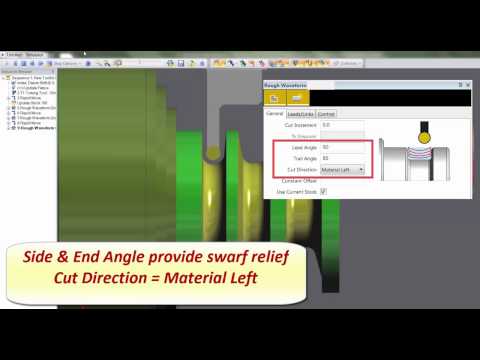

Waveform Turning - Edgecam 2015 R1 CAD-CAM

Based on our industry leading Waveform technology, Edgecam 2015R1 introduces a brand new Rough Waveform Turning cycle.

The toolpath maintains a constant cutting load enabling significantly faster cutting data and prolongs tool life. Similar to other turning commands, the cycle is sensitive to the stock condition thus producing zero ‘fresh-air cuts’.

www.edgecam.com

Workflow Multiple Turn Sequences - Edgecam 2015 R1 CAD-CAM

Edgecam 2015R1 introduces additional Workflow enhancements by supporting multiple machining sequences in both Turning and Milling environments. This allows not only the component, but also the Stock & Fixtures to be passed to new machining sequences. This enhancement promotes the use of one single CAM file to house multiple machining disciplines with in-process stock continually being updated.

www.edgecam.com

Centre Vice and 2nd Workflow Mill Sequence - Edgecam 2015 R1 CAD-CAM

Support for Self-Centering vices has been added to the Edgecam 2015R1 Fixture Manager. Furthermore, Workflow now supports multiple machining sequences (Turning and Milling) which allows not only the component, but also the Stock & Fixtures to be passed to new machining sequences. This enhancement promotes the use of one single CAM file to house multiple machining disciplines with in-process stock continually being updated.

www.edgecam.com