EDGECAM 2016 R1

The latest release of EDGECAM’s game-changing manufacturing software contains over 30 important new and enhanced items of CAD and CAM functionality for milling, turning, and wire EDM.

Pre Plunge Finish Groove Cycle

Turners now benefit from a new time-saving Pre-Finish Plunge option found in the Finishing Grooving cycle in EDGECAM 2016 R1. A single plunge cut is generated at the centre of a groove feature, and the cycle then continues to finish the feature in the usual way. As this removes most of the material it does away with the need for a Rough Grooving cycle.

Ramp Cut Strategy - Rough Turn

Following on from Waveform turning, the existing Rough Turn Cycle now features a new Ramp Cut strategy. This method is typically used for turning deep recesses with double-sided turning inserts...and extends tool life as the contact point on the insert is constantly changing, avoiding notching. The new strategy can be used with decreasing cut increments.

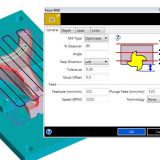

Images on Cycle Dialogs

Five more milling CAM cycles have been upgraded to use images and help tooltips. EDGECAM’s Product Manager, Simon Mee says: “This helps users to quickly understand the command function and also presents a consistent user interface.” The cycles are Parallel Lace, Pencil Mill, Face Mill, Flat Land Finishing, and Constant Cusp Finishing.

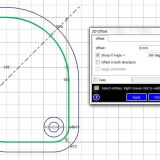

EDGECAM Workflow Solids | EWS

Enhancements have been made to EDGECAM’s 3D modelling software, EWS. A new 2D Offset Tool makes design creation easier. Common shapes and profiles are quickly duplicated and copies by an offset amount, reducing sketching time. More time is saved while creating constraints, as it is no longer necessary to exit the command – the dimension value is now immediately editable. And entities dynamically snap during the sketching phase. Also, an enhanced Arc command now includes a Set Diameter/Radius option, allowing multiple identical circles to be added to a sketch.

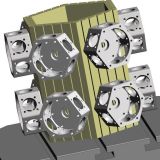

ACIS Solids | Performance Improvements

EDGECAM 2016 R1 sees the completion of memory-handling developments for working with multiple solid models. “Similar to Parasolid, Inventor and Granite files, users will now see noticeable performance improvements when working with ACIS models. This is achieved by only storing a single solid model – when duplicates are required EDGECAM creates references to the original geometry. Customers working with tombstone parts or sub-spindle lathes will reap significant benefits from this new functionality.”

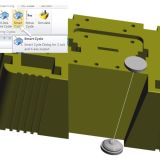

Operation Upgrades

A number of significant upgrades have been made to the Operations function, which is used in particular by new or infrequent EDGECAM programmers as a quick and easy way to develop complex toolpaths. Roughing, profiling, turning, and 4- and 5-axis commands have been enhanced, as well as the addition of a new chamfering operation.

Roughing Operation

The roughing operation is now stock-aware, and adopts the Waveform toolpath strategy. In addition, the rough turn operation now supports the B-axis...and the 4- and 5- axis operations can now directly pick on the solid model.

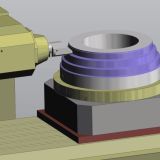

Simulator Update Stock Improvements

A function used for both milling and turning operations now saves additional time on the Update Stock command. “Through intelligent coding, the command no longer needs to process the graphical aspects of the machine set-up,” says Simon Mee. “This means the Machine Simulator can focus on pure toolpath. Further performance improvements have been made to the simulator when dealing with large toolpaths such as roughing and 5-axis cycles. The simulator now groups multiple cuts intelligently, to provide an optimum performance benefit.”

Feature Finder | Partial Holes

A further enhancement to the Automatic Feature Finding command means users can set a Partial Hole Angle when creating features. The value will control which hole features can be detected, and eventually machined. “This is particularly useful when the overall feature includes a hole or partial radius, and removes the need to manually create a hole feature or arc entity,” says Simon Mee.

Machine Tool Configuration improvements

New functionality has been added to the area of machine tool configuration – continuing the evolution of catering for milling machines with turning capabilities, EDGECAM 2016 R1 has introduced full support for head-table machines, including support for Siemens, TNC and ISO programming languages.

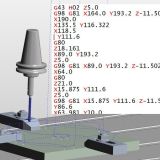

Extended Collision Detection

Building on enhancements from previous releases, EDGECAM 2016 R1 now offers extended collision detection and improved NC output for machining holes. Working in unison with the Update Fixture command, the Hole Cycle avoids collisions with fixtures by using clearance and retract values parameters. Simon Mee says this feature is especially beneficial when non-uniform clamps are used. “The cycle’s ‘link’ moves are minimised. As they’re calculated from the local fixture height, this reduces cycle time considerably. “As a result of this, the program output has been improved, as the specific retract value can be used in canned cycles.

Wire EDM

Wire EDM users benefit from a new Smart Cycle machining command. This combines 2-axis and 4-axis wire machining into one function, by analysing the input geometry shape. It guarantees that the output code always matches the feature shape, without the user needing to do anything else.

EDGECAM 2016 R1 also introduces a ‘Test For Separation / Slug Removal’ function into the wire EDM simulator. “Users can examine if slugs of material can become detached from the main stock body. The simulation test displays all separations, and shows which direction they’ll take. By knowing of any problems at this stage, users can decide whether to change the machining process. This is especially valuable on complex 3D shapes, where it’s not always obvious if separation is possible.”

EDGECAM 2016 R1 also introduces a ‘Test For Separation / Slug Removal’ function into the wire EDM simulator. “Users can examine if slugs of material can become detached from the main stock body. The simulation test displays all separations, and shows which direction they’ll take. By knowing of any problems at this stage, users can decide whether to change the machining process. This is especially valuable on complex 3D shapes, where it’s not always obvious if separation is possible.”